A Murder of Crows

When I first started weaving knotted pile about ten years ago, it was just for the pleasure of it. I planned to make a bag, one bag, and then get back to what I was doing at the time, mostly fabric weaving and bead weaving.

I found I really liked the knotting technique, really-really liked the end product, and was having fun. I did a few more bags. Then a few more. I put a bag or two in shows, other people liked them. Then someone asked me to show them how.

Well. I was already teaching weaving, spinning and dyeing classes, what's one more class? But the equipment I had for weaving this technique was somewhat specialized, no longer made, or made in far away foreign countries to which I had no ready access. I had to come up with a plan.

The loom needed to be sturdy enough to hold the tight tension required. It needed to be able to adjust the warp, advanced the warp, and make two sheds. Pretty basic. After all, I thought, knotted pile textiles have been made on looms built of sticks and logs, pegged out with rocks and tensioned by sitting on the textile in progress. I should be able to come up with something that would suit.

Sarah Swett came to the rescue: she was using a modified PVC pipe loom for her tapestry classes, and gave me a set of plans. They were based on Archie Brennan's design for a copper pipe tapestry loom.

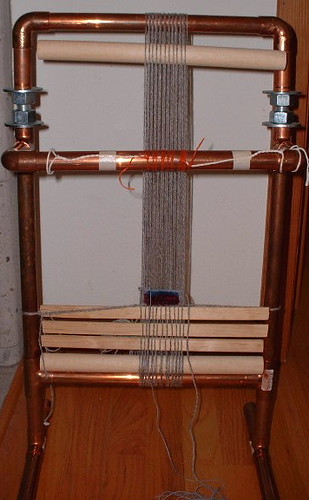

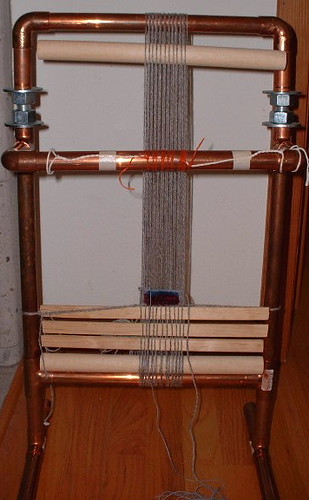

I modified it somewhat, adding a sturdy heddle bar, and it has worked quite well. For several years, I've been attached to this little loom:

I've made several out of PVC pipe for shipping around to classes. I also make them out of copper pipe, and I like the copper pipe version for its gleaming beauty, in addition to its very serviceable-ness. Weavers seem to be able to grasp its inherent utility quite handily.

But. Sometimes warping it is a challenge for people new to weaving, those whom I prefer to teach. Sometimes it is hard for new weavers get the hang of weaving on it. It requires a bit of tenacity to keep the warps in place, to not pull in or out during weaving and to maintain the proper sett.

Several years ago, I taught the pile class at Shuttles in Boulder, and my friend Cindy was in the class.

Cindy is not a weaver (and we had many fun things to find out about how to reach out to people who do not even know how to *wind a skein*). Cindy is a loom builder, she works for Schacht. She and I had discussions on loom building for this technique. Apparently she mentioned using other looms, those already on the market, like a tapestry loom or a rigid heddle loom, both of which I dismissed out of hand as not being sturdy enough. I don't remember the mention of rigid heddle, but Cindy does, and I believe her. This is where the murdering of several courses of crows comes in.

Fast forward a few years, to the process I am currently involved in: the writing a book on these weaving techniques. My publisher did not want the book to be based on the copper pipe loom: they wanted the loom to be readily accessible, something anyone can purchase, rather than have to build. I was disappointed, as I like this little loom, but I acquiesced. We settled on using a rigid heddle for all of the projects in the book.

Whoa! I was very pleasantly surprised. I tried two different versions of a rigid heddle loom, a 16" Ashford and a 15" Schacht Flip. I had to adjust a few things, use yarns that were slightly different from my usual selection, but the looms worked like a charm.

They are easy to set up too, making me start to wonder how I could incorporate them into class teaching. I recruited a couple of friends (read: guinea pigs)to try it out on their rigid heddles and weave some knotted pile:

This is Sue and Eileen (guinea pigs) and their projects at our retreat in Virginia City in June.

Emboldened, I set up a class at Shuttles, using the rigid heddle loom for knotted pile. Shuttles has a class set of looms, and they are willing to rent looms to students, who will need more than a 12 hour class to finish their projects. Cindy signed up for the class, as did Debbie, two people who had taken the previous version of the class using PVC pipe looms.

This past month I have taught two classes using the newer version of my now-based-on-the-book class projects. At GGFI, we used copper pipe looms. At Shuttles, we used the rigid heddle.

Oh. My.

Now, to backtrack a bit, the warping of the pipe loom seems simple enough to most people, but there are always a few for whom the process is daunting, strange, like rubbing your tummy and patting your head at the same time. It takes a bit of re-orienting, a bit of faith, to believe that the threads are going to do the right thing if you *just go this way*. Two people in five years have actually cried during the process. I try not to make people cry when they are learning to weave. It is bad form.

At the GGFI class (pipe looms) we had a crier. The Shuttles class (rigid heddle) was a piece of cake. The two people who had taken the class before on the pipe looms agreed with me: the rigid heddle loom is easier to set up, understand, quicker and does not cause tears.

I am going to have to think of a way to get classes using the rigid heddle:

Cindy recently reminded me that she had suggested the rigid heddle looms several years ago.

The crow is delicious, thank you.

I found I really liked the knotting technique, really-really liked the end product, and was having fun. I did a few more bags. Then a few more. I put a bag or two in shows, other people liked them. Then someone asked me to show them how.

Well. I was already teaching weaving, spinning and dyeing classes, what's one more class? But the equipment I had for weaving this technique was somewhat specialized, no longer made, or made in far away foreign countries to which I had no ready access. I had to come up with a plan.

The loom needed to be sturdy enough to hold the tight tension required. It needed to be able to adjust the warp, advanced the warp, and make two sheds. Pretty basic. After all, I thought, knotted pile textiles have been made on looms built of sticks and logs, pegged out with rocks and tensioned by sitting on the textile in progress. I should be able to come up with something that would suit.

Sarah Swett came to the rescue: she was using a modified PVC pipe loom for her tapestry classes, and gave me a set of plans. They were based on Archie Brennan's design for a copper pipe tapestry loom.

I modified it somewhat, adding a sturdy heddle bar, and it has worked quite well. For several years, I've been attached to this little loom:

I've made several out of PVC pipe for shipping around to classes. I also make them out of copper pipe, and I like the copper pipe version for its gleaming beauty, in addition to its very serviceable-ness. Weavers seem to be able to grasp its inherent utility quite handily.

But. Sometimes warping it is a challenge for people new to weaving, those whom I prefer to teach. Sometimes it is hard for new weavers get the hang of weaving on it. It requires a bit of tenacity to keep the warps in place, to not pull in or out during weaving and to maintain the proper sett.

Several years ago, I taught the pile class at Shuttles in Boulder, and my friend Cindy was in the class.

Cindy is not a weaver (and we had many fun things to find out about how to reach out to people who do not even know how to *wind a skein*). Cindy is a loom builder, she works for Schacht. She and I had discussions on loom building for this technique. Apparently she mentioned using other looms, those already on the market, like a tapestry loom or a rigid heddle loom, both of which I dismissed out of hand as not being sturdy enough. I don't remember the mention of rigid heddle, but Cindy does, and I believe her. This is where the murdering of several courses of crows comes in.

Fast forward a few years, to the process I am currently involved in: the writing a book on these weaving techniques. My publisher did not want the book to be based on the copper pipe loom: they wanted the loom to be readily accessible, something anyone can purchase, rather than have to build. I was disappointed, as I like this little loom, but I acquiesced. We settled on using a rigid heddle for all of the projects in the book.

Whoa! I was very pleasantly surprised. I tried two different versions of a rigid heddle loom, a 16" Ashford and a 15" Schacht Flip. I had to adjust a few things, use yarns that were slightly different from my usual selection, but the looms worked like a charm.

They are easy to set up too, making me start to wonder how I could incorporate them into class teaching. I recruited a couple of friends (read: guinea pigs)to try it out on their rigid heddles and weave some knotted pile:

This is Sue and Eileen (guinea pigs) and their projects at our retreat in Virginia City in June.

Emboldened, I set up a class at Shuttles, using the rigid heddle loom for knotted pile. Shuttles has a class set of looms, and they are willing to rent looms to students, who will need more than a 12 hour class to finish their projects. Cindy signed up for the class, as did Debbie, two people who had taken the previous version of the class using PVC pipe looms.

This past month I have taught two classes using the newer version of my now-based-on-the-book class projects. At GGFI, we used copper pipe looms. At Shuttles, we used the rigid heddle.

Oh. My.

Now, to backtrack a bit, the warping of the pipe loom seems simple enough to most people, but there are always a few for whom the process is daunting, strange, like rubbing your tummy and patting your head at the same time. It takes a bit of re-orienting, a bit of faith, to believe that the threads are going to do the right thing if you *just go this way*. Two people in five years have actually cried during the process. I try not to make people cry when they are learning to weave. It is bad form.

At the GGFI class (pipe looms) we had a crier. The Shuttles class (rigid heddle) was a piece of cake. The two people who had taken the class before on the pipe looms agreed with me: the rigid heddle loom is easier to set up, understand, quicker and does not cause tears.

I am going to have to think of a way to get classes using the rigid heddle:

Cindy recently reminded me that she had suggested the rigid heddle looms several years ago.

The crow is delicious, thank you.

7 Comments:

I only cry when I have to wait too long for your blog.

I still have my rigid heddle loom that I bought over 35 years ago and used for a few years and then ten years ago used for a year before I purchased a floor loom. I am so glad I did not give it away or sell it! Thanks for a wonderful post.

I'm saving weaving for when my hands give in knitting. I would never have considered it at all if not for coming here, so far I've bought and then sold a rigid heddle loom (too big for me) and I'm dithering over a buying an inkle loom. You just give me so much to think about.

So which style of loom are you planning to use for SOAR this year?

I ask because I had planned to bring you the copper pipe loom I made in your class in Park City.

I'm visiting via the rhlooms yahoo group. I love your copper loom--will your book have directions for making one?

I too am curious which type we will use at SOAR, since I'll be taking your class! I like the pipe loom's looks better and I like the fact that you can make it yourself, it's sort of humble and yet beautiful at the same time. On the other hand, the rigid heddle loom does look easy and ready to go...

I'm one of your SOAR students too and I can't wait. Like the others I'm curious. I have a standing PVC pipe loom that a friend made me for Christmas last year that sounds like it might fit the bill. I can't wait for SOAR! I just know we're going to have a blast!

Post a Comment

<< Home